Watch for overhead hazard. These include telephone lines, tree branches, signs, building overhangs and other obstabcles

Ensure terrain surrounding the aerial lift is stable and clear of debris. Many accidents happen when the aerial lift shifts due to uneven surfaces.

Account for the unique demands of outdoor aerial lift work, especially in colder climates where ice and snow are a big concern.

Slow & steady wins the race. When raising an AWP, it’s recommended to travel at a reasonable speed.

Confirm max load capacity. Tip-overs and similar accidents are often caused by overloading the aerial lifts’s max weight requirements.

Wear the necessary protective gear. This includes gloves, hardhats, reflectors and other safety apparel.

Get up-to-date training. Initial or renewal training for new and veteran aerial lift operators is a great way to ensure safe, effective aerial lift production.

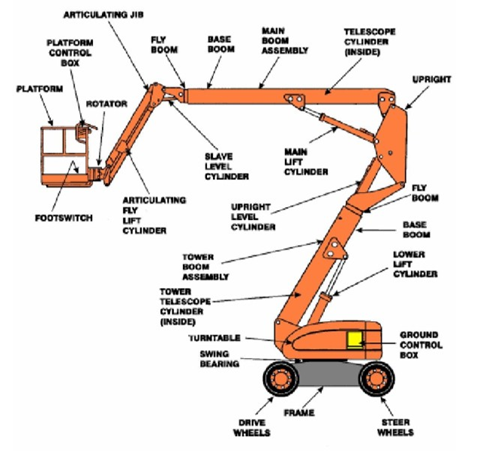

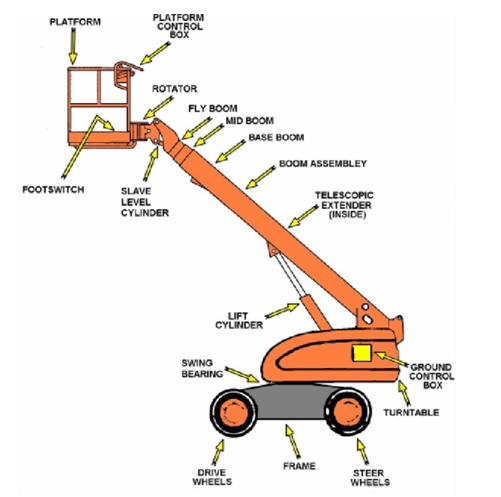

Know thy machine. Whether you’re an experienced operator or new to the job-reading user manuals and maintenance procedures is a great way to familiarize yourself with your machine.

Check to see if your industry is in line with new WELLDONE injury and accident reporting procedures. As of January 1, 2022, the list is based on the Indian Industry Classification System (IICS).

If an accident happens, report it within 24 hours to WELLDONE. Again, this is new WLLDONE legislation set for enactment on January 1, 2022

© Welldone Handling Services | Designed & Maintained By ITology